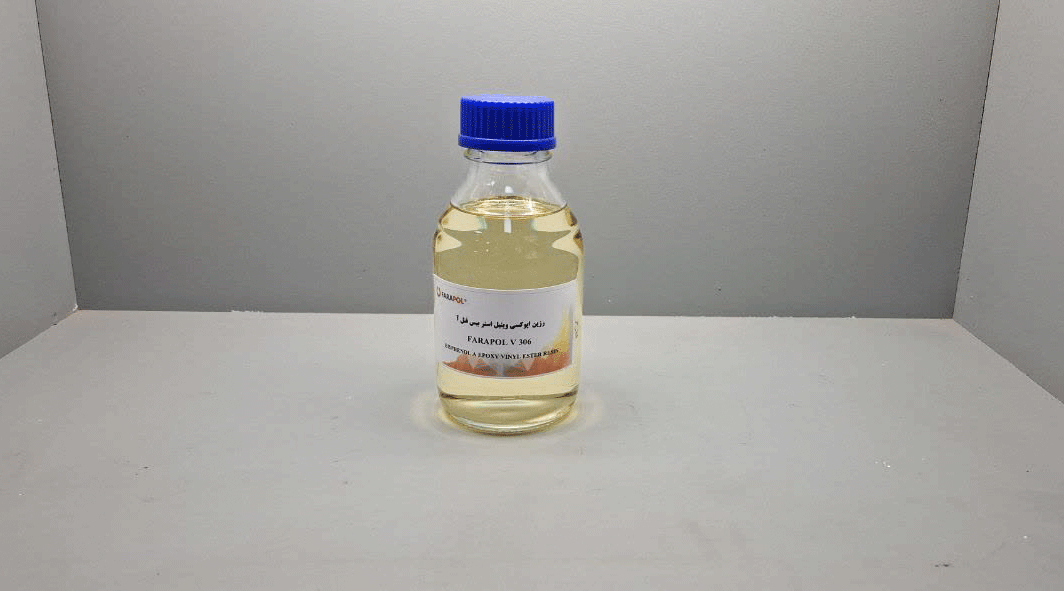

Vinyl Ester Resin Based On Epoxy Bisphenol A

Farapol: V 306

Vinyl ester resin based on bisphenol A (Farapol V 306) is a specialty molding resin that offers unique properties such as high temperature resistance and high Heat Deflection Temperature (HDT). This resin is an ideal choice for molding and industrial mold manufacturing due to its outstanding mechanical properties and economy.

Outstanding Features of Farapol V 306 Vinyl Ester Resin

- High Deflection Temperature (HDT):

Farapol V 306 vinyl ester resin is specifically designed to withstand high temperatures. An HDT above 100°C means that the resin resists deformation under load at high temperatures. This feature makes this resin excellent for industrial and automotive mold production.

- High resistance to temperature and abrasion:

Due to the special chemical structure of this resin, its high resistance to heat and abrasion makes it an excellent alternative for industrial molding. These properties are especially critical for the production of molds that are exposed to extreme temperature conditions.

- Appropriate for precise molding:

Farapol V 306 resin is specially designed for the molding process. Outstanding mechanical properties such as high strength and abrasion resistance make it ideal for producing precise and long-lasting molds.

- Economical:

In addition to its outstanding technical properties, this cost-effective resin is an economical choice for the molding industry. The combination of high performance and low production cost makes it an excellent choice for industrial molding projects.

Applications:

Vinyl ester resin based on bisphenol A (Farapol V 306) is used in various industries such as automotive, shipbuilding, electronic components manufacturing and other advanced industries. Due to its excellent heat and abrasion resistance, this resin is very suitable for producing precise and high-quality molds in high-temperature conditions.

The reasons for choosing Farapol V 306 vinyl ester resin:

- Excellent resistance to temperature and abrasion

- High technical performance in precise molding

- Cost-effective to reduce production costs

- Tested in reputable laboratories with available results

Farapol V 306 vinyl ester resin is a reliable and economical choice for precise molding and industrial mold production, helping you to reduce costs while also ensuring high quality in mold production.

Conclusion:

Farapol V 306, with its outstanding features such as high HDT, temperature and abrasion resistance, as well as being economical, is the best option for industrial molding processes and precise mold production. This resin has been tested in reputable laboratories and the results are available.

For more information and test results, you can contact the sales technical support department.